IP, RWTH

The construction industry has great potential for robotic automation as a result of the current challenges it faces:

CCR

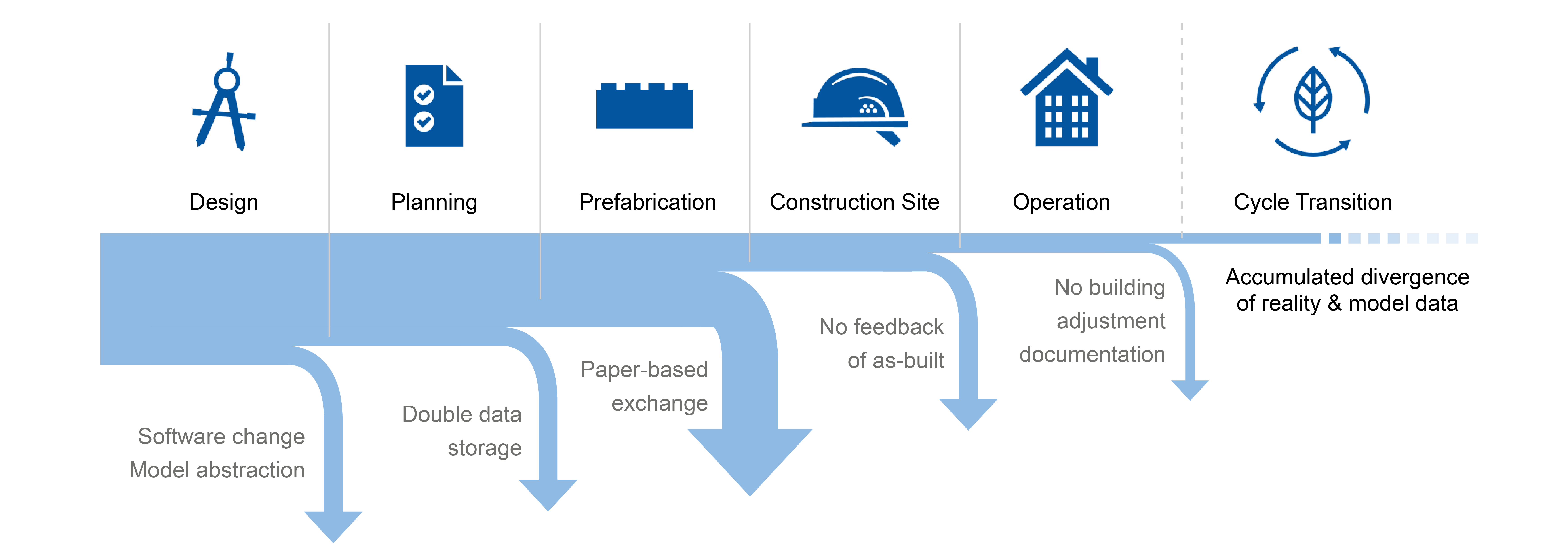

Picture: Loss of Digital Information Throughout a Building’s Lifecycle

CCR

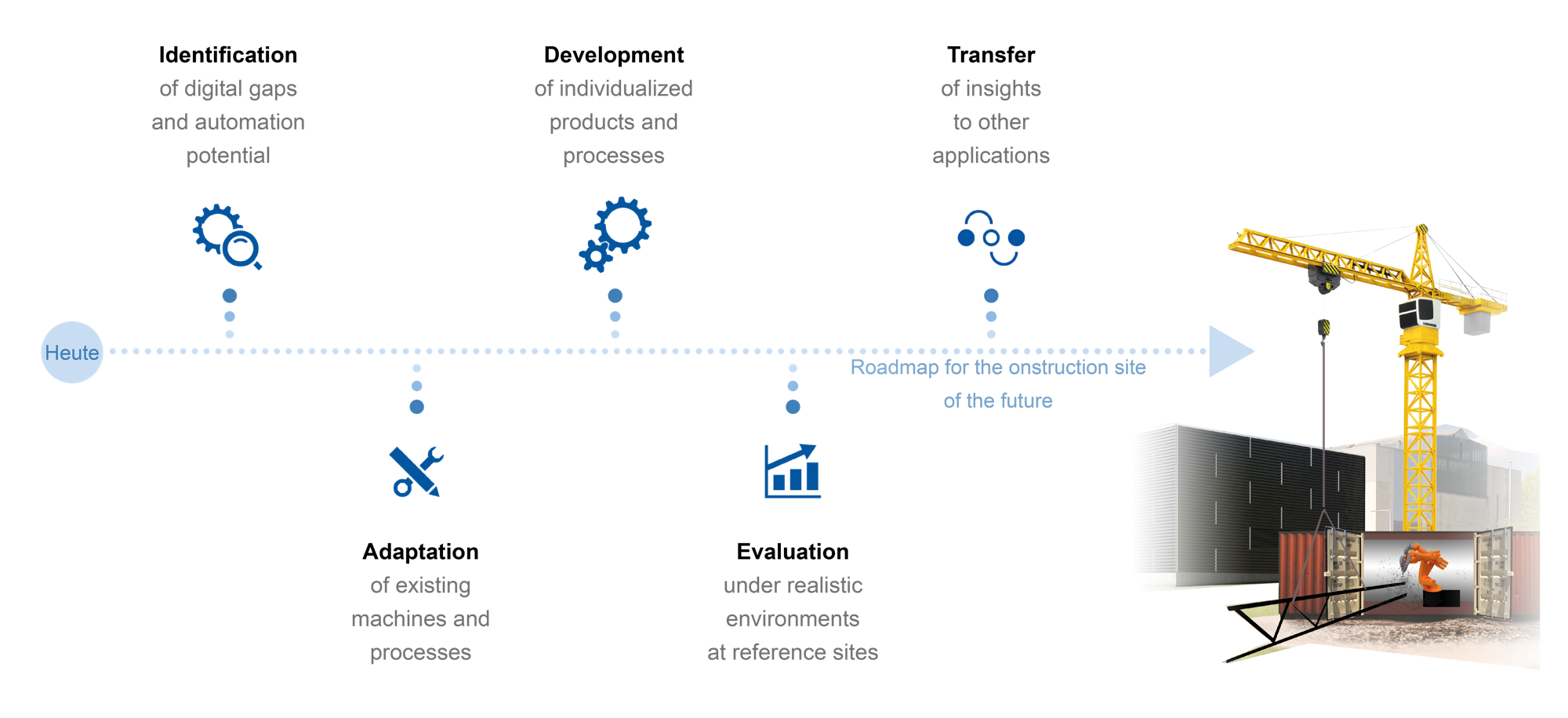

Picture: Roadmap of the Center Construction Robotics for the Scientific Development of Future Building Production

The stronger integration of design and process software requires new interfaces, standards and particularly user concepts. The center can accelerate these developments with demonstrators, prototypes and a reference construction site for testing. The same applies to the transformation of construction machinery and production facilities. The research infrastructure of the RWTH offers our members world class facilities and know-how for the development and validation of their products.

The research construction and construction sites scheduled for the RWTH Aachen Campus will enable our consortium to develop automation-compatible construction systems and test them under realistic conditions. These facilities are also available for training and further education. In addition, the members are provided with office space on and near the reference construction site so that the developments can be integrated into the members’ own activities in rapid coordination cycles.

IP, RWTH

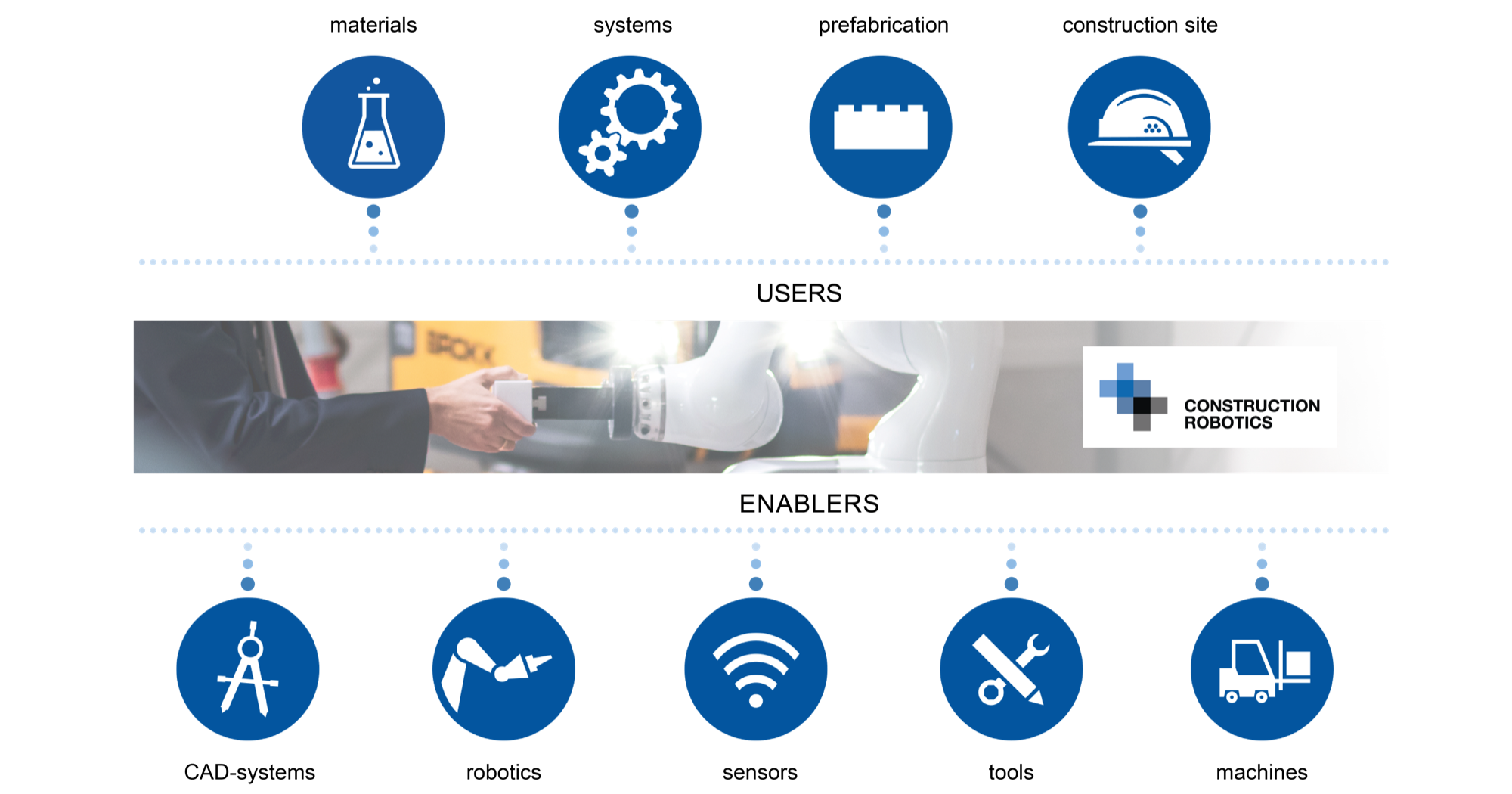

In order to advance digitalization in the construction industry and the automation of construction sites, we develop flexible automation solutions for construction processes. The following aspects play an key role at our center towards strengthening the value chain of the construction industry:

Technology transfer from highly automated industries to the construction industry

Effective procurement of data for the individual processes of construction stakeholders from the common BIM data source

Systems for the design of tailor-made tools to safeguard know-how

Interfaces for the use of automation solutions in the construction industry

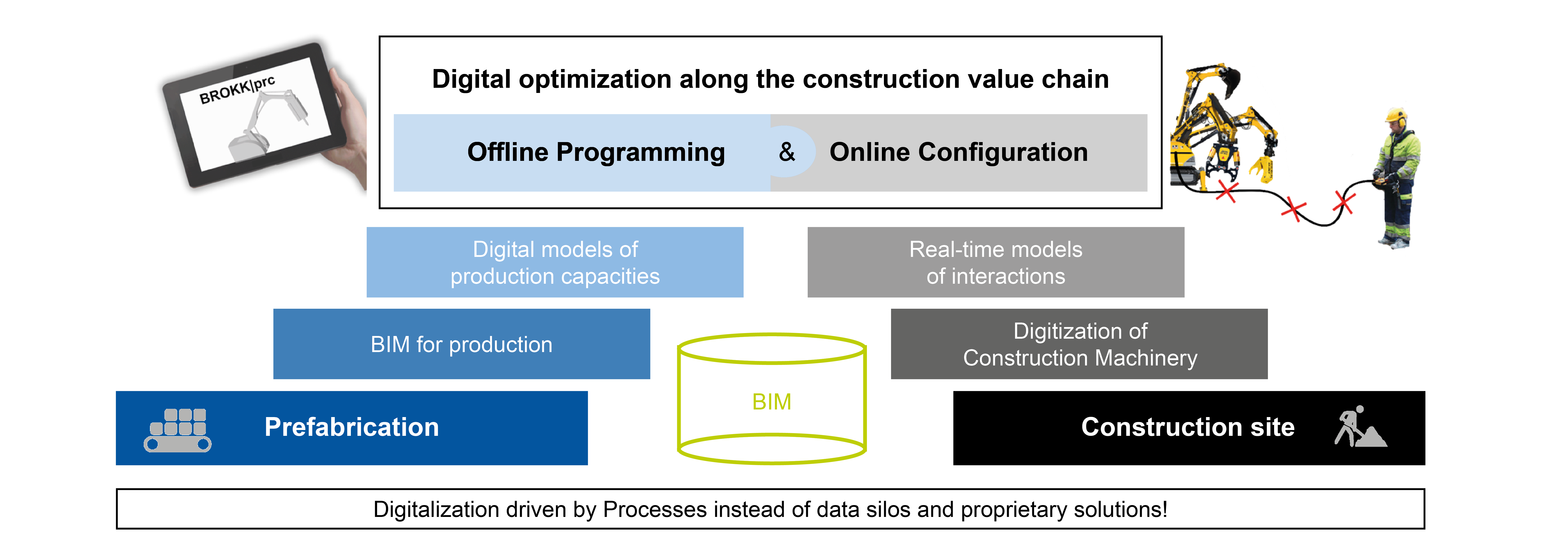

The center aims to automate construction from two directions: in a bottom-up process, starting from pre-fabrication, as well as from advances in on-site production. This combination allows for the identification of higher-level issues and process-based strategies. Detached from individual products or data silos, common working methods can be created along the value chain.

CCR

Picture: Strategy for the concurrent digitization of prefabrication and on-site processes along the construction value chain

IP, RWTH

Technologies can be developed in a user-centered manner and immediately evaluated by both manufacturers and users. New products and processes are thus created along the value chain of the construction industry, making the members leaders in the field of construction robotics.

CCR

Picture: The Center Construction Robotics’ strength is based on the collaboration of technology users and enablers from the construction industry

Have we sparked your interest? We would be happy to design individual cooperation possibilities for you – just write us a message! You can find out more about membership in the Center Construction Robotics here.

The chair of Individualized Production in Architecture researches intuitive systems for the use of construction robots, from the design and planning stages, through prefabrication and assembly to the deconstruction. Automation and technical consulting for construction processes are further fields of activity.

The Institute of Steel Construction researches both steel construction as well as composite construction methods in interdisciplinary topics such as windpower, timber and glass construction as well as light weight structures. The emphasis lies on the development of innovative and multifunctional facade systems.

One focus for Production Metrology and Quality Management lies in production integrated metrology and flexible automation of large scale assembly processes. Technical competence in the fields of positional measurements over large workspaces, computer vision and sensor technologies is complemented with expertise regarding quality and innovation management systems.

We measure our success by the success of our members. Less than a year has passed since we were founded, but we can already look back on the first fruits of interdisciplinary cooperation with our members and research partners. The challenges of digitalization and our built environment can only be solved together.

Chief Operating Officer

Management Assistance

Management Assistance

Project Management

Project Management

Project Management

Project Management

IT Administration

Technical Management

CCR Team

Photo: (from left) Christoph Heuer, Baris Cokcan, Stefanie Steinfeld, Burak Yirmibes, Markus Kuhnhenne, Sigrid Brell Cokcan, Victoria Jung, Jannik Oslender, Robert Schmitt, Zhao Zongquan

We are working on cyber-physical systems and further innovative technologies in communication and network control that aim to improve the efficiency, safety and sustainability of the construction industry through the use of automation and robotics. Our team is committed to develop and implement in Europe`s first large scale test bed at Campus Melaten Reference Construction Site beeing part of the 5G Industry Campus Europe and collaborating with industry and research partners.

We are looking for a research assistant who has experience in the acquisition, processing and management of industrial and research projects to take over the set-up and implementation of real test scenarios on the reference construction site Campus Melaten and has intentions for a doctorate in the field of construction robotics.

We look forward to meeting you!