18. September 2023

Press release

Since 2020, research has been conducted on the transformation of construction at the 4,000 m² Reference Construction Site, which moved from Campus West to Campus Melaten in 2023. The Reference Construction Site serves as a real laboratory in which robot technologies, software solutions, and innovative teaching, working, and communication approaches are tested under real conditions. Prof. Sigrid Brell-Cokcan, Chair of Individualized Production and Scientific Director Center Construction Robotics, says: “As a crowdsourcing project, the Reference Construction Site is open to all interested parties, fellow citizens, industry partners, start-ups, students and researchers. Another form of collaboration is project partnership based on a fair use principle: a collaboration in time-limited, targeted pilot projects. Any company that gets involved gets to use the site.” This is of particular interest to small and medium-sized companies, which – often without their own research and development departments – approach the center with targeted questions in order to quickly obtain answers as part of proof-of-concept projects. “The digitization of construction machinery is revolutionizing the construction industry. Smart technologies are increasing efficiency, reducing costs and improving safety. Machines are becoming smart partners on the construction site of the future,” says Christian Klein, Managing Director at Schulte Transportsysteme GmbH, pleased with the results achieved in the Diver project.

Since the start of joint research in the ecosystem of the RWTH Aachen Campus, the CCR has been attracting more and more project partners to discuss the issues of the future and jointly develop solutions for current challenges such as climate change, reuse of materials and automation in the construction industry. The European industry consortium currently includes PORR AG, Hilti Cooperation, EIFFAGE, KUKA DEUTSCHLAND GMBH, Autodesk GmbH, Doka GmbH, LEONHARD WEISS GmbH & Co. KG, ALIMAK GROUP, Fundermax GmbH und RIEGL Laser Measurement Systems GmbH. “The collaboration with RWTH Aachen University and other industry partners in the Center Construction Robotics is crucial to find a relevant approach for the future of one’s own business, especially in the areas of digitalization, robotics, social, community development and the environment. This is also an accelerator for Research to Market,” says Jean-Marie DOLO, Director of Technology and Innovation at EIFFAGE.

One of the most significant projects is the EU-funded TARGET-X project with a total volume of €14 million. The aim is to accelerate the digital transformation of the key construction industry through large-scale trials in various test environments. Using 5G technologies, functions such as localization, digital twin and sensor data fusion with various communication technologies will be tested at the Reference Construction Site. The 5G.NAMICO project, funded by the Ministry of Economic Affairs, Industry, Climate Protection and Energy of the State of North Rhine-Westphalia and led by the Fraunhofer Institute for Production Technology IPT, is investigating how the 5G mobile communications standard can be used in the construction and mining industries. Peter Wildemann, Project Manager Digitalization and Automation at LEONHARD WEISS GmbH & Co. KG: “We can only meet the ever-growing challenges of the industry together. Networking and automation is a constant dialog between all parties involved. The CCR together with the Reference Site Aachen offers us all a perfect platform to bring ideas and visions from and for the construction industry a little closer towards reality.”

As part of 5G.NAMICO, based on the findings of previous projects, a 5G network from Ericsson has now been installed at the Reference Construction Site to explore and exploit the benefits of the technology. A future research topic is the connection to a cloud to orchestrate multiple networked construction machines via 5G and enable low-latency and stable control. At the same time, students of the international master’s program Construction & Robotics can directly implement the findings in research-guided master’s theses in cooperation with industry partners.

On the occasion of the event, the best student theses of the past semesters of the master’s program will be awarded. “Digitalization in the engineering disciplines always succeeds when it is developed and ultimately implemented using concrete application scenarios. The Reference Construction Site creates precisely these framework conditions for this and thus makes an important contribution to the digital transformation of the construction industry” – Prof. Thomas Bergs, Spokesperson of the Production Engineering profile area and member of the Board of Directors of the Machine Tool Laboratory WZL at RWTH Aachen University.

Quotes

The Center Construction Robotics closes the digital gaps in the construction industry from planning through production to realization. In an interdisciplinary and consortial alliance of international industrial companies and cross-faculty university institutes at RWTH Aachen University, intelligent processes, machines and business models are being developed and designed for this purpose across the entire construction value chain. Jointly, the center researches and develops key technologies in hardware, software and process design. In the process, not only the indirect planning processes, but also the entire construction site construct as an essential part of the construction industry are taken into consideration, rethought, disruptively designed and implemented. www.construction-robotics.de

Building Cluster | RWTH Aachen Campus

The Construction cluster develops and tests new technologies and materials for deployment in construction. The productivity of materials, labor and equipment on site is optimized, and on-site execution is improved and accelerated through integrated planning tools and automation. This will enable more efficient and faster execution of what have been, in some cases, very lengthy approval and launch processes. In the future, a combination of artificial intelligence and machine learning can take construction to the next level of development. In order to make productive, digital tools usable, the cluster is also dedicated to the corresponding qualification of employees. https://www.rwth-campus.com/forschung/cluster-bauen/

The members

Since the start of the initiative, the reference building site has attracted more and more industry partners. The consortium includes well-known companies such as PORR AG, Hilti Cooperation, EIFFAGE, KUKA DEUTSCHLAND GMBH, Autodesk GmbH, Robots in Architecture, Doka GmbH, LEONHARD WEISS GmbH & Co. KG, ALIMAK GROUP, Fundermax GmbH and RIEGL Laser Measurement Systems GmbH. They support the reference site financially, infrastructurally and with expertise from practice.

The projects

Since the Center Construction Robotics began its work more than five years ago and now carries it out intensively on the Reference Construction Site, numerous projects have been initiated, carried out and already completed. Here is a current selection:

ROBETON

Rising raw material prices and climate change require a rethink in the handling of existing material resources and existing buildings. By digitally upgrading a demolition machine from the BROKK DA GmbH company to a (partially) automated robot, a new sustainable process for the safe, controlled deconstruction and subsequent reuse of concrete components as a source of secondary building products was developed at the Chair of Individualized Production at RWTH Aachen University. The ROBETON research project is funded by the Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR) on behalf of the Federal Ministry of Housing and Urban Affairs (BMWSB) with funds from the Zukunft Bau research grant and was awarded second place in the 2022 BAUMA Innovation Prize in the research category. In addition, the project is supported by the project partners Hilti Cooperation and Brokk DA GmbH as well as the associated project partners PORR AG, EIFFAGE, LEONHARD WEISS GmbH & Co. KG, HKS Dreh-Antriebe GmbH, Kerschgens Werkstoffe & Mehr GmbH, IMF Group and igus GmbH.

Enable Redevelopment 4.0

Building envelope refurbishment is gaining increasing market potential from an economic and sustainability perspective, and faces increasingly drastic challenges due to the shortage of skilled workers. By 2030, the market potential of building envelope refurbishment is estimated at 400 billion euros with a demand for over 300,000 employees. This corresponds to an increase of more than 50 percent of the current number of employees, which can hardly be met under normal circumstances.

The Center Construction Robotics has set itself the goal of automating the renovation of building shells using construction robotics and thus counteracting the shortage of skilled workers. With the research project “Enable Refurbishment 4.0”, the state of North Rhine-Westphalia is supporting this project with the funding program “Digitalization of the Construction Industry and Innovative Construction”. Over a period of two years, the project team will be working on the further development of an assistance system for the automated assembly and handling of facade panels for building refurbishment, thus making a contribution to the construction site of the future. The project is supported and promoted by the members of the Center Construction Robotics.

DIVER

The aim of this project is to equip a mini crane with low-tech sensor technology for digitizing and simulating the laying processes of large-format building materials. Increased construction efficiency is intended to counteract the increasing shortage of skilled workers. The hardware development including the requirements, the installation of the sensors and the connection to the simulation environment as well as the creation of the simulation environment was made possible by two master theses of the master program Construction & Robotics. The project is supported and accompanied by the Chair of Individualized Production at RWTH Aachen University and the companies Xella International GmbH and Schulte Transportsysteme GmbH.

EConoM

EConoM is a research project funded by the German Federal Ministry of Digital Affairs and Transport as part of the InnoNT funding call, which is supported by the project sponsor TÜV Rheinland Consulting GmbH. In order to secure the German and European construction industry as well as to advance the technology and innovation location Germany, the research and development of automation of construction sites are indispensable. The combination of key technologies from 5G campus networks, edge computing, artificial intelligence and digital twin will enable enormous automation potential and further optimization of workflows and processes within the construction site.

Within the framework of EConoM, innovations in the fields of artificial intelligence (AI) and 5G campus networks are to be used to improve the quality of construction work, increase work safety on the construction site, reduce overall costs and shorten construction times. To achieve this, edge computing, AI and communication must be enabled on construction sites in a comprehensive, robust, easy-to-handle and trouble-free manner. It is coordinated by the partners Fraunhofer FOKUS, Fraunhofer Heinrich Hertz Institut, HOCHTIEF ViCon GmbH, planen-bauen 4.0 GmbH, UNIBERG GmbH, Zeppelin Rental GmbH, Construction Robotics GmbH, TÜV Rheinland, Lehrstuhl für Individuali-sierte Bauproduktion, RWTH Aachen University.

5G.NAMICO: Networked, Adaptive Mining and Construction

As part of the 5G.NAMICO research project, 5G is to be used in the construction and mining sector of the future. Based on the findings of previous projects such as 5G-Industry Campus Europe, a 5G network is now to be installed at the Reference Construction Site of RWTH Aachen University and in an underground mine to exploit the benefits of the technology. One challenge here is the adverse and changing environments: Dust, vibrations and humidity place demands on a dynamic 5G network that must withstand the harsh operating conditions. 5G technology, which was developed for use in industrial environments and open areas, must therefore be further developed. The use of 5G in construction and mining has the potential to automate processes and reduce personnel workloads. A prerequisite for this is the development of improved safety concepts that protect people in partially and fully automated processes and at the same time advance the digital transformation. In order to use 5G on construction sites and in mining in the future, the project will first look at selected use cases that deal with the automation of individual work processes and the safety aspect.

The 5G.NAMICO project is funded by the state of North Rhine-Westphalia via the Ministry of Economic Affairs, Industry, Climate Protection and Energy of the State of North Rhine-Westphalia and is technically managed by the Fraunhofer IPT. This is a “5G.NRW” project, with the responsible project management organization Julich. The project is supported by the partners Chair of Individualized Production, RWTH Aachen University, Chair for Sustainable Raw Material Extraction MRE, RWTH Aachen University, Kabelwerk Eupen AG, Ericsson GmbH, GHH Fahrzeuge GmbH, BAT Bergbau Service GmbH, BROKK DA GmbH, Liebherr-Werk Biberach GmbH, PORR AG and LEONHARD WEISS GmbH & Co. KG, the development and evaluation of the use case on the construction site is coordinated by the Center Construction Robotics.

TARGET-X

The vision of TARGET-X is to strengthen key economic sectors in Europe by integrating 5G and 6G and accelerating digital transformation. TARGET-X pursues this vision by providing testbeds for different domains (energy, automotive, construction, manufacturing and robotics). The development is expected to lead to new business models. The project brings together information technology providers, operational technology providers and SMEs, in a European context. The reference site of RWTH Aachen University is part of one of the 5 European real laboratories, which is an ideal test environment for great 5G and 6 G processes. The TARGET-X project has received funding from the Smart Networks and Services Joint Undertaking (SNS JU) under the European Union’s Horizon Europe research and innovation programme under Grant Agreement No 101096614. The project is supported by the Fraunhofer Institute for Production Technology (IPT), ERICSSON GmbH, RWTH Aachen University through the three chairs (Chair for Individualised Construction Production, Machine Tool Laboratory WZL and Institute for Automation of Complex Power Systems), IDIADA Automotive Technology SA, Construction Robotics GmbH, Fundacio Privada I2CAT, Internet I Innovacio Digital a Catalunya, Marposs Societa Per Azioni, Fundingbox Accelerator SP. z o. o, Ericsson Arastirma Gelistirme ve Bilisim Hizmetleri Anonim Sirketi, Marposs Monitoring Solu-tions GmbH, 5G Communications for Future Industry Verticals SL, Neutroon Technologies S.L, Mitsubishi Electric Europe B.V. German Branch; FundingBox Communities SL, Qualcomm CDMA Technologies GmbH.

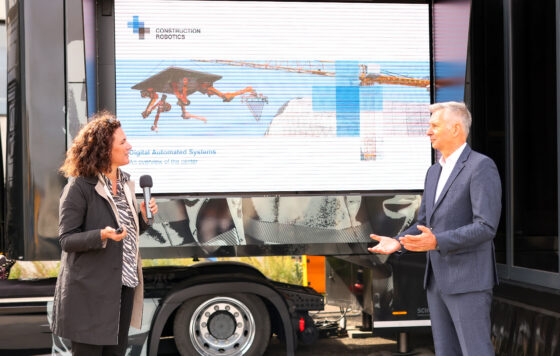

Press photos

High-resolution images of our event on September, 19th and the reference construction site can be downloaded here. Please note the stated copyright “CCR / Steindl”. This image material may only be used for editorial purposes in the context of reporting on the event on 19.09.2023/the reference construction site and with the specified copyright (CCR / Steindl). In the event of publication, please send us a specimen copy or a Links to the online article.

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

CCR / Steindl

-

-

-

-

-

CCR

-

CCR

-

CCR

-

CCR

-

CCR

-

CCR

-

CCR

-

CCR