9. September 2024

Press release

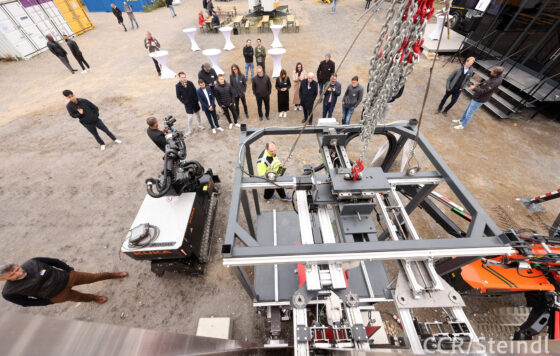

The Reference Construction Site is the first 5G-equipped construction site for research and teaching in Europe, a test site and itself a demonstration project with an area of 4,000 m². As part of the 5G Industry Campus Europe, it serves as a real lab for researching communication and data interfaces as well as the digitalization and automation of construction sites and construction processes. The aim is to test various communication technologies and the use of cyber-physical systems for construction applications in dynamic and harsh environments. An interdisciplinary team of scientists from RWTH Aachen University is conducting research here together with European and local industrial partners in numerous projects. The mix of interdisciplinary knowledge and practical experience from the industry is invaluable for jointly solving the digitalization gap, current challenges in automation and future requirements of the circular economy in the construction industry. “The North Rhine-Westphalian funding program “Digitization of the construction industry and innovative construction” supports groundbreaking research in the partially automated renovation of existing buildings on the reference construction site in Aachen”, says Daniel Sieveke, Secretary of State at the Ministry of Regional Identity, Local Government, Building and Digitalization of the State of North Rhine-Westphalia.

On the Reference Construction Site, innovations from Technology Readiness Level 4 can be tested in a real, controllable environment before they are used on real construction sites. This significantly minimizes the entrepreneurial risk, especially for small and medium-sized enterprises (SMEs). Universities, on the other hand, benefit from insights into practical problems in industry. Students can work closely with industry partners as part of their Master’s theses, which increases the visibility of companies among young talent and promotes the transfer of well-trained workers to the construction industry. “The Reference Construction Site is a Living Lab. Here, our young scientists have the opportunity to re-invent and help shape their future jobs in the construction industry together with industry partners and RWTH researchers”, says Prof. Sigrid Brell-Cokcan, Chair of Individualized Production and Scientific Director Center Construction Robotics. In addition, companies benefit from new technologies as beta testers and can influence developments at an early stage. This creates potential market advantages in the introduction of digitalization and automation and thus strengthens Germany as an industrial location. The free access to state-of-the-art technical equipment and infrastructure in the FAIR Use Principle enables start-ups and SMEs to test their own developments. “The Reference Construction Site and the collaboration with the students and researchers at RWTH Aachen University helps us to drive our own developments forward faster and more efficiently, especially in challenging times”, says Christian Klein, Managing Director at Schulte Transportsysteme GmbH.

A world innovation is the presentation of the first functional model for a mobile KUKA construction site robot, the KMR Iontec Outdoor, as a hybrid of a tracked mobile platform and an industrial robot, which was developed in cooperation with KUKA GmbH and the Chair of Individualized Production and the Machine Tool Laboratory WZL at RWTH Aachen University as part of a DFG (German Research Foundation) grant.

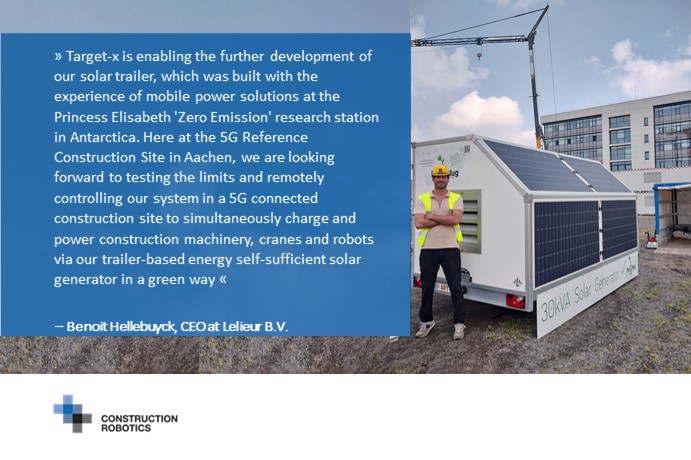

The collaborative research projects, in which real demonstrators are realized on the Reference Construction Site together with industry partners, are unique. For example, the “ReStage” multi-material demonstrator developed in the TARGET-X project impressively combines collaborative cooperation along the entire value chain from architects and planners to construction companies and sub-contractors with university researchers. The €12 million TARGET-X project serves as a pre-competitive European platform for the development and testing of various digitalization and automation approaches through the sustainable storage of machine, BIM and construction component data in order to achieve a future circular recovery of building materials according to the cradle-to-cradle principle. To show the deconstructability of the ReStage Demonstrator, the aim is to dismantle the building in Aachen and rebuild it at bauma 2025. “Target-x is enabling the further development of our solar trailer, which was built with the experience of mobile power solutions at the Princess Elisabeth ‘Zero Emission’ research station in Antarctica. Here at the 5G Reference Construction Site in Aachen, we are looking forward to testing the limits and remotely controlling our system in a 5G connected construction site to simultaneously charge and power construction machinery, cranes and robots via our trailer-based energy self-sufficient solar generator in a green way”, says Benoit Hellebuyck, Managing Director at Lelieur BV.

All in all, the Reference Construction Site offers a unique, participatory forum for researching pioneering construction processes and technologies under real conditions and accelerating innovative transformations in the construction industry. The public is welcomed with free access to the Reference Construction Site every year as part of the “Open Campus Week” to interact with all funding and project partners. “The digital transformation and industrialization of the construction industry can only be solved together”, says Prof. Thomas Bergs, Spokesperson of the Production Engineering Profile Area at RWTH Aachen University.

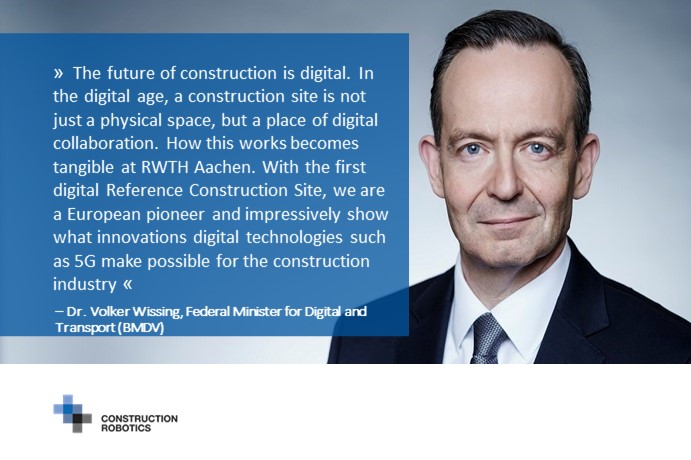

The InnoNT, Innovative Network Technologies programmes of the Federal Ministry for Digital and Transport (BMDV), Smart Networks and Services Joint Undertaking are currently funding the Reference Construction Site as part of Horizon Europe and the Ministry of Regional Identity, Local Government, Building and Digitalization of the State of North Rhine-Westphalia.

Quotes

The Center Construction Robotics closes the digital gaps in the construction industry from planning through production to realization. In an interdisciplinary and consortial alliance of international industrial companies and cross-faculty university institutes at RWTH Aachen University, intelligent processes, machines and business models are being developed and designed for this purpose across the entire construction value chain. Jointly, the center researches and develops key technologies in hardware, software and process design. In the process, not only the indirect planning processes, but also the entire construction site construct as an essential part of the construction industry are taken into consideration, rethought, disruptively designed and implemented. www.construction-robotics.de

Building Cluster | RWTH Aachen Campus

The Construction cluster develops and tests new technologies and materials for deployment in construction. The productivity of materials, labor and equipment on site is optimized, and on-site execution is improved and accelerated through integrated planning tools and automation. This will enable more efficient and faster execution of what have been, in some cases, very lengthy approval and launch processes. In the future, a combination of artificial intelligence and machine learning can take construction to the next level of development. In order to make productive, digital tools usable, the cluster is also dedicated to the corresponding qualification of employees. https://www.rwth-campus.com/forschung/cluster-bauen/

The members

Since the start of the initiative, the Reference Construction Site has been attracting more and more industry partners. The consortium includes well-known companies such as PORR AG, EIFFAGE, KUKA DEUTSCHLAND GMBH, Autodesk GmbH, Robots in Architecture, Doka GmbH, LEONHARD WEISS GmbH & Co. KG, ALIMAK GROUP, Fundermax GmbH and RIEGL Laser Measurement Systems GmbH. They support the Reference Construction Site financially, infrastructurally and with expertise from practice.

The projects

Since the start of the Center Construction Robotics more than five years ago, numerous projects have been initiated, implemented and already completed on the Reference Construction Site.

EConoM

EConoM is a research project funded by the German Federal Ministry of Digital and Transport (BMDV) as part of the InnoNT funding call, which is supported by the project funding agency TÜV Rheinland Consulting GmbH. In order to secure the German and European construction industry and to promote Germany as a location for technology and innovation, research and development into the automation of construction sites is essential. The combination of key technologies from 5G campus networks, edge computing, artificial intelligence and digital twin will enable enormous automation potential and the further optimization of workflows and processes within the construction site.

As part of EConoM, innovations in the areas of artificial intelligence (AI) and 5G campus networks will be used to improve the quality of construction work, increase work safety on the construction site, reduce overall costs and shorten construction times. To achieve this, edge computing, AI and communication must be made possible on construction sites in a way that is comprehensive, robust, easy to use and trouble-free. It is coordinated by the partners Fraunhofer FOKUS, Fraunhofer Heinrich Hertz Institute, HOCHTIEF ViCon GmbH, planen-bauen 4.0 GmbH, UNIBERG GmbH, Zeppelin Rental GmbH, Construction Robotics GmbH, TÜV Rheinland, Chair of Individualized Production, RWTH Aachen University.

TARGET-X

The aim of TARGET-X is to strengthen key economic sectors in Europe through the integration of 5G and 6G and to accelerate the digital transformation. TARGET-X pursues this vision by providing testbeds for different domains (energy, automotive, construction, manufacturing and robotics). The development is expected to lead to new business models. The project brings together information technology providers, operational technology providers and SMEs in a European context. The Reference Construction Site of RWTH Aachen University is one of the 5 European real-world laboratories, which is an ideal test environment for great 5G and 6G processes. The TARGET-X project has received funding from the Smart Networks and Services Joint Undertaking (SNS JU) under the European Union’s Horizon Europe research and innovation program under grant agreement No 101096614.

The project is supported by the Fraunhofer Institute for Production Technology (IPT), ERICSSON GmbH of RWTH Aachen University through the three chairs (Chair of Individualized Production, Machine Tool Laboratory WZL and Institute for Automation of Complex Power Systems), IDIADA Automotive Technology SA, Construction Robotics GmbH, Fundacio Privada I2CAT, Internet I Innovacio Digital a Catalunya, Marposs Societa Per Azioni, Fundingbox Accelerator SP. z o. o, Ericsson Arastirma Gelistirme ve Bilisim Hizmetleri Anonim Sirketi, Marposs Monitoring Solutions GmbH, 5G Communications for Future Industry Verticals SL, Neutroon Technologies S.L, Mitsubishi Electric Europe B.V. German Branch, FundingBox Communities SL, Qualcomm CDMA Technologies GmbH.

CLOUD56

CLOUD56 is a research project funded by the Federal Ministry for Digital and Transport (BMDV) as part of the InnoNT funding announcement, which is supported by the project funding agency TÜV Rheinland Consulting GmbH. In CLOUD56, innovative network technologies are being researched by implementing a virtualization of the radio access network (so-called CloudRAN) and the industrial application hardware on a common platform for the first time. This approach offers potential savings in the implementation and integration of new 5G networks as well as in the implementation of 6G and other future RAN technologies. The approach of a common server technology between RAN core and industrial application services is also an important step towards Green IT.

In the CLOUD56 project, the Chair of Individualized Production is also pursuing the goal of developing new methods for the robot-assisted prefabrication of steel components. The starting point is the connection of industrial robots and their sensors to the cloud infrastructure in order to enable efficient collaboration between different automation technologies and employees. In addition to making the system configuration more flexible in line with the Plug & Produce concept of Industry 4.0, this connection enables (partial) virtualization of the necessary control systems. To this end, robot-supported steel construction production plants in Industry 4.0 systems are to be modularly connected to each other via 5G technology and subsystems virtualized via the cloud infrastructure. By connecting to linked data-based information systems, real production information can be recorded on a process-related basis and thus inform the virtual plant models in order to both simplify the inspection of the manufacturing processes carried out and enable sustainable process optimization for flexible steel construction processes. The project is being coordinated by the Fraunhofer Institute for Production Technology (IPT) and carried out together with the project partners Ericsson GmbH, SMS digital – SMS group GmbH, IconPro GmbH, Neura Robotics GmbH, Richard Wolf GmbH, SurgiTAiX AG and RWTH Aachen University. RWTH Aachen University is represented by the Chair of Individualized Production (IP), Machine Tool Laboratory (WZL), Chair of Medical Technology (MediTec) and IT Center (ITC). Associated partners of the project are Dräger Werk AG & Co. KGaA, OR.NET e.V., NVIDIA GmbH and Marposs Monitoring Solutions GmbH.

Enable Redevelopment 4.0

The main goal of the Enable Redevelopment 4.0 research project is to develop an initial plug & produce prototype for semi-automated, scaffolding-free assembly in building refurbishment. The developments and investigations into the use of digitally controlled robots with rope hoist systems will create potential and new incentives for the exterior renovation of façade elements, for example, which will have a significant impact on increasing the quality and efficiency of craft businesses by automating and relieving them of physically strenuous work. At the same time, the prototype contributes to the preservation of building stock and thus to promoting the circular economy of construction by sustainably renovating buildings instead of demolishing them. The prototype comprises a platform that is positioned on the façade using a cable hoist system, in this case a mobile Jekko crane. A special gripper system stabilizes the platform on the façade substructure. At the center is a robot that precisely positions and attaches the façade panels. The system learns from the first demonstration by the foreman and is based on the principle of “programming by demonstration”, taking environmental factors into account. Trajectories and movement characteristics are learned automatically. Once the first row of façades has been installed by the foreman, the crane-robot platform takes over the rest of the installation. The operator only has to carry out quality and safety checks. The process requires neither a digital building model nor predictive planning and adapts geometrically to different existing buildings, eliminating the need for planning, surveying and scaffolding. This improves schedule and cost reliability and promotes new business models in building envelope renovation. The robot can also be equipped with various tools to serve other applications. The project was funded by the “Digitalization of the construction industry and innovative construction” funding initiative of the Ministry of Regional Identity, Local Government, Building and Digitalization of the State of North Rhine-Westphalia and developed with the support of the practice partners of the Center Construction Robotics at RWTH Aachen University with Fundermax GmbH, KUKA AG and Jekko Deutschland GmbH.

ORCHESTRA

The ORCHESTRA project focuses on developing a concept for making construction data open and available. The project is a consortial project of the CCR members (PORR AG, LEONHARD WEISS GmbH & Co. KG, KUKA DEUTSCHLAND GMBH, EIFFAGE, ALIMAK GROUP, Autodesk GmbH und RIEGL Laser Measurement Systems GmbH). The aim of the CCR Orchestra project is to define the requirements and implement a standardized description of data exchange for construction site processes. Linked data is the basis for linking different processes, sources and stakeholders and making information available to everyone transparently through semantic queries. Using a defined example process, the initial requirements are developed to identify which technical developments are still missing and which existing ontologies can be built upon.

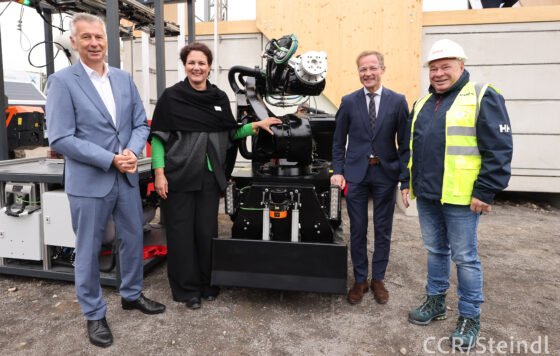

Press photos

High-resolution images of our event on September, 17th and the reference construction site can be downloaded here. Please note the stated copyright “CCR / Steindl”. This image material may only be used for editorial purposes in the context of reporting on the event on 17.09.2024/the reference construction site and with the specified copyright (CCR / Steindl). In the event of publication, please send us a specimen copy or a Links to the online article.